DETROIT, MICHIGAN — AUGUST 2, 1941

Two engines roared to life on test stands inside Packard’s East Grand Boulevard plant. The sound was unmistakable—

the fierce, mechanical snarl of a Rolls-Royce Merlin, the same engine that kept Britain alive during the Battle of Britain.

But these weren’t British.

They were American-built Merlins, created from British blueprints so complex they looked like sacred scripture.

Around the test stands, executives, engineers, and Army officers watched politely.

None of them knew the truth.

They weren’t just witnessing an engine test.

They were witnessing a revolution.

Because hidden inside those engines were changes so profound, so invisible, so technically audacious, that they would reshape aviation history.

Packard hadn’t simply copied the Merlin.

They rebuilt it from the molecular level—

and they did it by breaking every rule Rolls-Royce thought was unbreakable.

I. The Mustang Problem: Beauty Without Breath

Early 1942.

The U.S. Army Air Forces had the P-51 Mustang, a fighter that looked like it could win the war:

fast

agile

deadly

long-range

stable

Below 15,000 feet, it was a masterpiece.

Above that?

A choking, gasping disappointment.

The problem wasn’t the airframe.

It was the Allison V-1710 engine, which relied on a single-stage supercharger. At bomber altitude—25,000 to 30,000 feet—horsepower collapsed to desperation levels.

And American bombers, cruising over Germany at those altitudes, were being slaughtered.

America didn’t need a new fighter.

It needed a new engine.

II. The Merlin: Britain’s Hand-Built Jewel

Britain had already solved the altitude problem with the Rolls-Royce Merlin:

a two-stage, two-speed supercharger

handmade tolerances

individually matched cylinder heads

supercharger impellers balanced by artisans

14,000 hand-fitted parts

thread systems using Britain’s arcane Whitworth standard

Rolls-Royce engines weren’t manufactured.

They were crafted.

And Britain, fighting for its life, couldn’t build them fast enough.

They needed American production.

But they did not understand what they were asking.

III. Detroit Takes the Challenge — and Immediately Realizes the Truth

When Packard’s engineers examined the Merlin’s blueprints in September 1940, they saw the truth:

This engine cannot be mass-produced.

Not as-is.

Not even close.

The problems were staggering:

1. Measurement Systems Were Incompatible

Britain used one “imperial” system.

America used another “imperial” system.

Neither matched.

Conversions weren’t simple math.

They required understanding the intent behind the original tolerances.

2. British Whitworth Threads Didn’t Exist in America

Every bolt.

Every nut.

Every fastener.

All cut to a 55° Whitworth angle—unknown in the U.S.

3. Rolls-Royce Engines Relied on Skilled Fitting

Rolls-Royce built engines like violins:

craft workers hand-filed parts

bearings were individually sized

impellers were tuned like instruments

Detroit didn’t work that way.

American mass production required:

perfect interchangeability

no filing

no tweaking

no artisans

A bolt made on Monday needed to fit an engine built on Thursday.

Perfectly.

The British engineers were skeptical.

This wasn’t how engines were meant to be built.

Then Packard’s lead engineer, Jesse G. Vincent, said something legendary:

“Your tolerances are too loose for us.”

The room fell silent.

And the American reinvention of the Merlin began.

IV. Packard’s Breakthrough: Reinventing the Merlin Without Changing It

Over the next 11 months, Packard engineers:

created 6,000 new technical drawings

redesigned every manufacturing process

tightened tolerances across the board

invented new tooling

built custom thread machines

improved metallurgy

preserved every dimension

lost zero horsepower

They didn’t change the Merlin.

They changed how a Merlin could be built.

The Bearing Miracle

Rolls-Royce used copper-lead bearings.

Packard replaced them with silver-lead-indium, a combination that:

reduced friction

ran cooler

lasted longer

Rolls-Royce objected.

Then they tested them.

Then they adopted them.

The Whitworth Thread Solution

Instead of Americanizing the threads, Packard did the unthinkable:

They built entirely new tooling to make British Whitworth threads—

to American automotive precision.

British parts and American parts became completely interchangeable.

Rolls-Royce engineers were stunned.

The Supercharger Revolution

Packard modernized the impeller casting process so precisely that:

balance weights became unnecessary

assembly time plummeted

engine reliability soared

They introduced dynamic balancing equipment no British factory owned.

The Cooling System Overhaul

Packard redesigned internal coolant passages for better flow, simpler casting, and easier maintenance—without changing performance.

Piece by piece, Packard did what seemed impossible:

They kept the Merlin’s soul,

but replaced its body with something stronger.

V. August 2, 1941 — Two Engines Roar, and History Tilts

The first Packard-built Merlin—designated V-1650-1—ran flawlessly on the test stand.

Power output identical.

Fuel consumption identical.

High-altitude performance identical.

Except for one thing:

Packard could build thousands of them.

Fast.

Winston Churchill allegedly wept when he heard the news.

He understood what it meant:

Britain would not run out of engines.

And America was about to get the fighter it desperately needed.

VI. The Mustang Grows Teeth

The P-51 Mustang with an Allison engine was good.

The P-51 Mustang with a Packard Merlin was unstoppable.

437 mph

combat ceiling over 40,000 feet

range to escort bombers to Berlin and back

climb rate unmatched

high-altitude agility

legendary reliability

The Germans called it:

“Der Amerikanische Raumjäger.”

The American Space Fighter.

It changed the war.

Bombers suddenly had a guardian angel.

The Luftwaffe broke.

And the Mustang entered legend.

VII. Production: Where Packard Proved the Impossible

By 1943, Packard built engines faster than airframes could be produced.

Peak output:

400 engines per week.

By 1945, Packard had built 55,523 Merlins—

more than all Rolls-Royce factories in Britain combined.

This wasn’t copying.

This was industrial symbiosis:

British aeronautical genius

American manufacturing genius

Together, they made something neither country could have achieved alone.

VIII. The Lasting Legacy: The Engine That Outlived the War

Packard’s methods—precision mass production, statistical control, tolerance discipline—became the foundation of modern aerospace engineering.

Every jet engine today descends from the systems Packard pioneered.

Even now:

WWII Mustangs still race at Reno

Packard Merlins push 3,800+ horsepower

Lancaster bombers still fly with Packard engines

The howl of a Merlin is more than a sound.

It is:

a British idea

perfected by American innovation

multiplied by Detroit

immortalized in combat

It is the scream of a partnership that changed the sky forever.

IX. The Truth of the Packard Merlin

The story is not:

“America fixed a British engine.”

Nor is it:

“Britain designed the perfect machine.”

The truth is deeper and more beautiful:

The Merlin became great because both nations brought their strengths—

and trusted the other’s.

British elegance

American pragmatism

British innovation

American precision

British engineering

American scalability

Two philosophies.

One engine.

A war turned on its axis.

X. Listen Closely

The next time you hear a P-51 Mustang:

that high-pitched Merlin whine

that liquid, rolling growl

that mechanical symphony at 30,000 feet

You are hearing:

British mathematics

American machinery

6,000 redesigned drawings

14,000 integrated parts

55,000 engines

and one perfectly solved impossible problem

You are hearing history’s greatest engineering duet.

A masterpiece born not from one nation’s brilliance—

but from two nations choosing to build something together.

News

The Brutal Coincidence that Cost Germany 25,000 Soldiers

The Trap at Mons September 1944 Southern Belgium Two tides were flowing across the fields. One was ragged, gray, and…

The Tank American Crews Asked For – Why the M26 Pershing Missed WWII’s Big Battles

July 27, 1944 Near Saint-Lô, Normandy The Panther’s gun thundered. Inside the turret, the shockwave rolled through steel, through bone….

(CH1) The Secret Sherman: Why German Troops Couldn’t Destroy US M4 Tanks | Wet Stowage Explained

July 27, 1944Near Saint-Lô, Normandy The Panther’s gun thundered. Inside the turret, the shockwave rolled through steel, through bone. The…

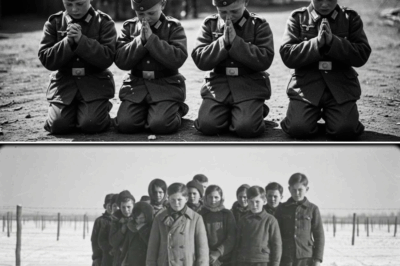

(CH1) German Child Soldiers Braced for Execution — Americans Brought Them Coca-Cola Instead

Story title: The Coca-Cola in the Snow The last days of the war tasted like dirt and metal. Thirteen-year-old Oskar…

Former Goebbels Officer Expects Torture in US Prison Camp—What He Gets Instead Breaks Him Completely

Story title: From Lies to Headlines 1. Surrender with a Satchel of Lies May 8, 1945 Southern Bavaria The last…

(CH1) Japanese Admirals Thought The US Navy Was Crippled — Until 6 Months Later At Midway.

TOKYO — DECEMBER 8, 1941 The air in the Imperial Japanese Navy headquarters is thick with cigarette smoke and triumph….

End of content

No more pages to load