December 1944. Inside a dimly lit hanger on the outskirts of Reclan, the air smelled of oil metal and defeat. Germany was still fighting, but every man in that room already sensed the outcome. Under the glare of a single flood light stood a massive engine crate marked in fading stencils. Pratt and Whitney aircraft R2800.

It had been salvaged from the wreck of an American P47 Thunderbolt shot down over northern France. The fuselage was twisted and burned, but the engine, this enormous round 18cylinder beast, had somehow survived intact. Technicians from the Luftvafa’s experimental division gathered around it like priests about to open a relic. They whispered among themselves, “So this is what powers their flying milk bottles?” one muttered using the mocking nickname German pilots had given to the P-47s.

To them, the American fighter was a brute heavy, clumsy a machine that defied every principle of elegant engineering. No one understood how it could climb so high, take so much punishment, and still come home. The Luftwaffa wanted answers. The order from Berlin was clear. Disassemble the captured engine. Analyze every component. find the secret. The crate was pried open with crowbars.

The mechanic stepped back as the light hit the metal 1,200 lb of alloy and power. The double row cylinders formed a perfect circle gleaming under a layer of grime. A junior engineer named Otto Henel ran his hand across the casing, tracing the embossed words double wasp. He had repaired hundreds of BMW 801s, the engine that powered Germany’s own FW190s. But this thing looked alien.

The cooling fins were thicker. The bolts oddly oversized the exhaust manifold arranged in a pattern none of them recognized. “Too heavy,” someone said dismissively. “The Americans overbuild everything.” Henchel didn’t reply. He had heard that before. He also knew that overbuilt sometimes meant built to last.

For a moment, the hangar was silent, except for the clink of wrenches and the hiss of kerosene lamps. Outside, snow drifted across the airfield, muffling the distant sound of artillery from the Western Front. Inside, the Germans began the slow ritual of dismantling a masterpiece they didn’t yet understand. As the cowling came off, a sweet metallic scent filled the room.

The first cylinder head revealed a precision of machining that made even the senior engineer pause. The threads were cut so finely that they seemed polished by light itself. There was no chatter, no tool marks, no imperfections. These were not parts made by hand. They were made by an industrial civilization operating at a scale Germany could no longer imagine. In that moment, the tone in the hanger changed. The jokes faded.

The laughter stopped. Henchel realized what he was seeing was not just a piece of machinery, but the physical embodiment of America’s industrial might. Every surface told a story of mass production perfected, of factories running day and night without fear of bombing of supply lines that stretched across oceans.

He understood that each P-47 engine rolling off an assembly line in Connecticut came from a nation that could afford to build a thousand more. When they finally rotated the engine to expose the rear section, a murmur rippled through the team. A massive turbine housing sat behind the crankase, larger than any supercharger they had ever seen.

Henchel leaned closer, following the maze of stainless steel ducts feeding into the intake manifold. It’s not a simple supercharger, he whispered. It’s a turbocharger driven by exhaust gas. The chief engineer frowned. That was impossible. Turbocharging required heatresistant alloys Germany didn’t possess. Nickel, chromium, cobalt, all of them rationed, all of them scarce.

Yet here it was, humming silently in captured glory. The older men exchanged uneasy glances. They had spent years perfecting engines like the BMW 801 and Dameler Benz 605, tuning them for power and efficiency. But this this was brute strength forged through abundance. It wasn’t beautiful. It wasn’t clever.

It was unstoppable. Outside the hanger, the wind howled across frozen runways. Inside, under the flickering lamps, a German mechanic stared at a machine that shouldn’t have been possible, and realized something that few dared to say aloud, the war had already been decided long before the first shot was fired.

Not by aces in the sky, but by men in factories who could turn steel into miracles faster than an empire could understand them. If you believe wars are won by brave pilots, type one in the comments. If you think they’re won by better machines, hit like. And if you want to uncover the next secret buried in history, subscribe now because this story is only beginning.

In the winter of 1944, the Luftvafa’s technical bureau was drowning in bad news. Squadrons once filled with veterans were now led by boys barely old enough to shave. Fuel stocks were rationed to the point that training flights had been reduced to 30 minutes a week. And yet, from the Western Front to the skies over Berlin, a strange new American fighter kept appearing bigger, heavier, louder than anything the Germans had ever seen.

The men in the intelligence office at Adlershoff called it the Thunderbolt. Reports from pilots sounded exaggerated, even absurd. We hit it dozens of times, one transmission read, and it kept flying. Another claimed a P47 had dived straight through a formation of FW190s, its guns roaring and vanished into the clouds before anyone could react.

At first, the high command dismissed these accounts as excuses. No airplane that size could fight like that. But then the wreckage started arriving. Crashed Thunderbolts were being recovered across occupied Europe, and the more they examined them, the less sense they made. Their engines were enormous. Their fuselages built like armored vaults. Even a single machine gun burst that would have torn through a messmitt barely left scratches on the Americans.

Luftwafa pilots who once mocked the flying milk bottle began to curse its name. One veteran from Yagashwatter, 26, the elite schlagoder wing, summed it up bitterly. They fly like anvils, and they fall on us the same way.

What truly alarmed German engineers wasn’t just the Thunderbolt’s toughness, but its altitude. On the eastern front, the Luftvafa had dominated with the FW19A, a low to medium altitude dog fighter. But over Western Europe, P47s were climbing beyond 30,000 ft, well above the operational ceiling of most German interceptors, and attacking from above with devastating speed.

The culprit was the engine, the Pratt and Whitney R2800 Double Wasp. At altitude where air was thin and temperatures could freeze metal solid, this engine somehow maintained full power. The BMW 801, by comparison, gasped for breath above 25,000 ft. Its mechanical supercharger unable to feed enough air to the cylinders. The Luftwaffa’s technical office launched a formal investigation.

They needed to know how the Americans had done it. Orders were sent to the Reclan test center to acquire and dissect any intact R2800 engine recovered from wreckage. The hope was simple. Find its secrets, copy them, and restore parody to the skies. But by then, Germany’s industrial reality was collapsing.

Allied bombers had leveled ballbearing factories in Schweinfort aluminum plants in Norway and fuel refineries in Pesht. Even if they discovered the secret replicating, it was another matter entirely. Still, the investigation proceeded. Pride demanded it. To understand what made the Americans different, one must understand how the Germans thought about machines. To the engineers of Dameler Benz and BMW, an aircraft engine was a masterpiece, a creation to be tuned, polished, and improved by craftsmen who believed beauty and precision were inseparable.

Each component was hand fitted, each bearing inspected by eye. The result was performance unmatched in the world when the materials were pure and the hand steady. But it was a system built for perfection, not for war. In America, the philosophy was the opposite. The R2800 wasn’t designed for artisans. It was designed for assembly lines.

Every bolt, every thread, every gasket was standardized so that thousands of factories across the country could build the same engine with identical tolerances. Instead of handcrafting, they used machines so precise that the difference between two pistons was measured in microns.

Where Germany built art, America built quantity and quantity in the harsh mathematics of war eventually becomes quality. By early 1944, this difference had turned into a strategic chasm. German pilots were fighting on two fronts with engines that required hours of maintenance after each sorty. American engines, by contrast, could fly dozens of missions with minimal servicing.

A single factory in Connecticut produced more R2800s in a month than Germany could build high-performance engines in a season. For the Luftwaffa, the captured P47 engine wasn’t just a technical curiosity. It was a question of survival. If they could understand how this massive machine worked, perhaps they could find a way to counter it.

That was why when the wreck of a thunderbolt fell near Kong and its engine was found largely intact, it was shipped across Europe under heavy guard. The crate that arrived at Reckland in December was more than just scrap metal. It was a symbol of everything Germany was losing altitude, speed, and time.

In a report to the Ministry of Armaments, a senior engineer wrote, “We believe the Americans have solved the altitude problem through wasteful use of materials and fuel.” He meant it as criticism, but the truth was darker. The Americans could afford to be wasteful. They had more aluminum, more fuel, more factories, and more men. The Thunderbolt was not a miracle of engineering.

It was the logical result of an economy that dwarfed its enemy. Still, the Germans couldn’t resist one final act of defiance. They would open the engine, study it, and prove that they could understand even if they couldn’t replicate.

Henchel and his team were selected for the job because they knew radial engines better than anyone in the division. When the crate arrived, they treated it not as a trophy, but as a challenge to their pride. Before the first bolt was turned, the chief engineer gave a short speech. Gentlemen, this engine is not magic. It is metal and mathematics, and both can be conquered. The men nodded.

None of them knew that within hours their certainty would begin to crumble. What they would find inside the double wasp wasn’t just superior engineering. It was an entire philosophy of war made tangible, one that valued reliability over elegance and production over perfection. If you believe victory comes from genius design, press one in the comments.

If you believe it comes from relentless production, hit like and stay tuned because what they found inside that engine would change everything they thought they knew about power altitude and the limits of human engineering. The hangar was silent except for the sound of tools. Each turn of a wrench echoed like a heartbeat.

Otto Henchel crouched beside the massive R2800, his gloved fingers tracing the bolts that held the cowling in place. The Americans had designed this engine like a fortress. Every joint was sealed, every connection reinforced. When the first layer of metal finally came free, a hiss of stale oil and burned residue escaped into the air.

a ghost of its last flight over France. The men leaned closer under the flood lights. The engine’s anatomy gleamed like sculpture. To a German mechanic’s eye, the construction was bewildering. The BMW 801 that powered the FW190 was compact, dense, and elegant. A triumph of efficiency. This American engine was its opposite oversized cylinders, thick walls, heavy clamps, redundant systems.

It’s absurd, muttered one technician. They’ve built it as if weight doesn’t matter. He wasn’t wrong. The R2800 weighed nearly a ton, almost twice as much as the BMW engine. But Henchel was beginning to sense something the others hadn’t yet seen. The parts didn’t just look heavy, they looked unbreakable.

He removed one of the cylinder heads and stared at the valve assembly. The machining was immaculate. Every thread was perfect. Each gasket fit so tightly that it seemed fused to the metal. He called over the chief engineer. Together they examined the finish under a magnifying glass. There were no burrs, no imperfections, no tool chatter.

It was the kind of precision one would expect from a watch maker, not from an engine built by the tens of thousands. Look at the uniformity, Henchel whispered. Every component could be swapped between engines, and it would still fit. That was the first revelation. German engines were hand fitted, tuned by skilled craftsmen who adjusted parts until they worked together. Each one was unique.

This American engine was different. It was interchangeable, a product of exact tolerances and machine perfection. Henchel realized that behind this engine wasn’t just engineering skill, but a production philosophy his country had never mastered. Then came the second revelation. As they dismantled the rear housing, they uncovered a massive circular assembly unlike anything they had ever seen.

The chief engineer frowned. This can’t be right, he murmured. The component was a turbine huge complex and connected to the exhaust ports by a web of polished steel ducts. When the Americans said turbo supercharger, the Germans had imagined a small mechanical compressor. This was something else entirely, a gas-driven turbine harnessing waste heat from the exhaust to force more air into the cylinders.

Henchel removed the casing carefully. Inside, a wheel of blades glittered under the lamplight. He touched the metal and drew his hand back immediately. The alloy was strange, smooth, hard, and faintly iridescent. They tested it with a file. The teeth barely scratched the surface. One of the metallurgists whispered, “This is not steel.” He was right.

It was inconel, a nickel chromium alloy that could survive temperatures above 700° C without deforming. Germany had experimented with similar metals, but never on this scale. Nickel was scarce. Chromium was reserved for armor plating. The Americans had built entire engines out of it. The realization spread slowly through the group. The reason the Thunderbolt could climb to 30,000 ft wasn’t magic.

It was metallurgy. The R2800’s turbo system allowed it to maintain sea level power even where the air was thin as mountain frost. The turbo’s exhaust piping alone stretched more than 15 ft, rooted through ducts that circled the engine-like veins. The Germans could see the logic, but not the practicality.

To build one of these, the chief engineer said quietly, “We would need half the resources of the Reich. They moved on to the cooling system. Here, too, the Americans had done something different. Instead of relying solely on air flow across the cylinders, they had built a labyrinth of baffles, oil lines, and intercoolers that distributed heat evenly across the entire engine. It was crude in appearance, but brilliant in effect.

The BMW 801 required constant monitoring to avoid overheating. The R2800 could run at full power for hours without burning a valve. As the night wore on, the hanger filled with the smell of hot oil and sweat. Henchel’s hands were black with grease, but his mind was racing. Every component he removed told the same story, redundancy, strength, and reliability.

This engine wasn’t designed for aces or one-off prototypes. It was designed for war, real war, where machines had to survive mud, cold salt, and inexperience. The Americans had built a weapon that could be flown by anyone, repaired anywhere, and mass- prodduced without compromise. When they opened the magneto housing, Henchel discovered yet another surprise.

The ignition system was double redundant. Two spark plugs per cylinder, two complete magnetos, twin distributors. If one system failed, the other would keep the engine running. In the Luftwaffa, such redundancy was considered unnecessary weight. Here it was standard practice. They build like they don’t care about limits, a mechanic muttered. They don’t have to, another replied.

At 2 in the morning, they rolled the turbine wheel under the light and measured its dimensions. The chief engineer calculated the rotational speed over 20,000 revolutions per minute. His pencil stopped halfway down the page. At these stresses, it should explode, he said. Unless, Henchel finished the thought for him, unless they know exactly how far they can push the metal.

The phrase hung in the air half admiration, half despair. By dawn, the R2800 lay disassembled across four workbenches, its guts exposed like the anatomy of some extinct creature. The Germans gathered around the pieces in silence. For years they had believed in their own superiority. Better pilots, better tactics, better technology.

But what they saw on those tables forced them to confront another truth. The Americans had mastered something more powerful than innovation. They had mastered scale. Every component of the R2800 told them that behind each Thunderbolt stood not a single engineer, but an army of machines, workers, and factories.

an industrial ecosystem built to outlast any enemy. Henchel picked up one of the pistons and held it to the light. The alloy was flawless, the surface polished like glass. He turned it over in his palm, feeling its weight. In another life, it could have been art. He thought about the pilots who had flown this engine, the young Americans who took to the air, knowing that somewhere back home, a thousand more engines waited to replace theirs.

That was a luxury no German pilot could imagine. He set the piston down carefully and spoke in a voice barely above a whisper. “We can copy the shape,” he said, “but not the soul.” No one disagreed. Outside the gray light of morning spilled through the hangar doors. The war was still raging, but in that cold silence, the men around the table understood what the front lines had not yet realized. The outcome was already written in metal.

If you think victory belongs to those who innovate, press one in the comments. If you believe it belongs to those who build without limits, hit like and subscribe because the story of what happened after that morning would reveal how a single engine changed the course of the air war forever. By the time the sun rose over Wland, the men in the hangar were still staring at the rows of disassembled components spread out on the tables.

The R2800 had been opened, measured, and studied, but the feeling it left behind wasn’t triumph. It was quiet awe mixed with something colder resignation. They had expected clever trick, secret patents, perhaps a new alloy or a hidden valve design.

What they found instead was something far more intimidating, the sheer perfection of repetition. Every part from the smallest bolt to the largest turbine blade was marked with serial codes that traced back to factories across the United States. Henchel held one in his hand, a connecting rod stamped with a neat set of numbers and letters, East Hartford, 1943, lot 128. To him it was both a signature and a taunt.

Each marking told the same story. This was not the product of a single genius or workshop. It was the output of a vast machine and industrial organism that stretched from Detroit to Connecticut to Los Angeles. Later that week, a detailed report from the Luftvafa’s technical division arrived from Berlin.

It included a set of statistics captured through intelligence channels. Henchel read them in silence. The United States was producing more than 850 aircraft engines per week, each tested, created, and shipped across the Atlantic. Over 15,000 Thunderbolts had already rolled off assembly lines by that winter. And more were coming. Corsair’s Hellcats, Marauders, all using the same R2800 heart.

Germany, by contrast, was struggling to build 200 fighter engines a month. Most of them assembled in underground factories, bombed so often that the workers had to finish parts by candle light. To an engineer, numbers tell their own kind of story. They are the language of possibility and of doom. When Henchel compared the figures, he realized that even if Germany somehow duplicated the R2800 exactly, they could never match the speed or scale at which America built them.

The Americans had made precision into a process. Germany had made it an art. One could be multiplied a thousand times. The other could not. Inside the hanger, Henchel began to disassemble the turbo housing for metallurgical samples. The lab analysis confirmed his suspicions. The turbine blades contained 22% nickel and 14% chromium metals Germany no longer possessed in quantity.

In 1943, the Reich’s stockpiles of nickel had fallen below half of what was needed for aircraft production. Chromium came mostly from mines in the Balkans now under Allied control. Even if they had the blueprints, the materials themselves were beyond reach. A metallurgist handed Henchel the analysis sheet. If we tried to cast this alloy with our current supply, he said quietly, it would shatter before it ever reached operating temperature. Henchel nodded.

Then it isn’t just the engine we can’t copy, he said. It’s the civilization that built it. Across the Atlantic, that civilization was operating at full throttle. In East Hartford, the Pratt and Whitney plant ran 24 hours a day. Workers rotated in three shifts, producing 2,000 engines a month, each identical to the last.

At night, the factory glowed like a furnace powered by electricity drawn from rivers and coal reserves untouched by enemy bombs. Precision lathes shaped steel to tolerances measured in microns. Entire neighborhoods in Connecticut existed to house the workers who built engines like the one lying disassembled in Henchel’s hanger. The Luftwaffa’s intelligence department compiled more comparisons.

The average American engine mechanic had access to over 300 specialized tools. In Germany, shortages meant many workshops had to share a single torque wrench among several teams. The Americans used alloys containing cobalt and malibdinum, while the Reich relied on recycled metals stripped from damaged aircraft.

The contrast wasn’t just in numbers. It was in philosophy. German engineers believed that perfection required human touch. that every machine carried the fingerprint of its maker. The Americans believed that perfection came from eliminating those fingerprints altogether. To them, reliability wasn’t art. It was arithmetic. The irony was cruel.

Henchel knew that a single R2800 engine could outlast three BMW 801s in combat hours. While the Luftwaffa’s fighters required major servicing after 25 hours of flight, the Thunderbolts engine could run more than 150 hours before overhaul. In the skies over Europe, that difference meant survival. He turned back to the table and studied the magneto housing again.

The Germans had always dismissed redundancy as wasteful extra weight for pilots to carry. But the Americans had built redundancy into every system accepting inefficiency to guarantee endurance. It was a logic born not of desperation but of abundance. That afternoon, Henchel wrote his report. He listed the technical observations in precise language, excellent alloy quality, remarkable thermal tolerance, unusual reliability at high manifold pressure.

But in the final paragraph, he allowed himself a rare moment of honesty. This engine represents a philosophy we cannot match. Its strength lies not in innovation, but in the industrial depth of its nation. It is a weapon of production as much as of flight. When the report reached Berlin, it was summarized in two sentences. For the Air Ministry, the American R2800 is unnecessarily heavy but highly robust.

Its power is derived from wasteful design and excessive material use. Bureaucrats underlined the phrase wasteful design, using it to justify the continued focus on lighter, more efficient German engines. None of them understood that this wastefulness was the secret to survival. Weeks later, a second R2800 arrived from another wreck. The engineers unpacked it with less enthusiasm.

They already knew what they would find. Still, they repeated the measurements, the weighing, the analysis. Each time, the results were the same precision power and reliability produced at a scale Germany could only dream of. Henchel began to keep his own private notes scribbled in the margins of his blueprints.

Every component is built for forgiveness, he wrote. They expect it to fail, and so they make sure it can. That single line captured the difference between the two empires. Germany designed to avoid failure. America designed to survive it. When he finished his final inspection that evening, he stood by the open hangar door and watched the snow drift across the runway.

The war was now being lost in ways no pilot could see from shortages, from exhaustion, from an enemy whose factories outproduced his own by 20 to1. The R2800 wasn’t a secret weapon. It was the proof that technology had become the servant of economy and economy had become destiny. If you believe the war was won in dog fights, press one in the comments.

If you believe it was won in factories, hit like and subscribe because in the next chapter, what these German engineers did with their discovery would determine the final shape of the air war. By the time Henchel’s report reached Berlin, the Luftvafa’s leadership was already trapped in a different kind of battle, one fought not with bullets, but with pride.

On paper, Germany still fielded the most advanced aircraft in the world. The ME262 jet promised to change the war’s direction. The FW190D was entering production, and the engineers at Messmmet were sketching designs that looked like something from another century. Yet behind those blueprints lay a truth that no one in the air ministry wanted to read aloud.

The empire had no fuel, no nickel, and no time. In February 1944, the head of aircraft development, General Feld Marshall, Hehard Mil, reviewed the technical brief on the captured American engine. His assistant summarized it cautiously. Their design prioritizes reliability and mass manufacturer, not elegance. Milch frowned. So, it’s crude, he asked.

Yes, sir, came the reply, but it works. Milch closed the folder. We will not copy crude. That sentence sealed more than a dozen decisions that would haunt Germany’s air war until the end. The R2800’s lessons were clear, but they were lessons the German system could not accept.

The Reich’s engineers believed that technical superiority equaled victory. They saw the war as a contest of invention, not endurance. In America, the philosophy was reversed. Build simple, build strong, and build so many that losing a hundred meant nothing. That difference now defined the skies over Europe. As 1944 unfolded, the Thunderbolt squadrons became a force the Luftwaffa couldn’t counter.

With its turbo supercharged engine, the P47 could escort bombers deep into Germany, dive at 500 mph, and climb above any piston aircraft the Reich possessed. Its pilots called it jugsh short for juggernaut, and the name fit perfectly. German fighters that tried to intercept the B7s found themselves hunted by these blunt-nosed monsters that refused to die.

Each time a squadron returned from combat, Allied intelligence counted the results. Thunderbolts averaged seven times fewer engine failures than German fighters on comparable missions. Even damaged, they often made it home. In one case, a P47 pilot flew more than 200 m with a piston cracked clean through the engine, still turning.

The R2800 didn’t just provide power, it provided forgiveness. At Recklin, Henchel’s team received a TUR directive investigate turbocharger adaptation for German engines. But it was a hopeless order. Germany’s factories lacked the nickel to cast turbine blades and the machining capacity to produce the delicate housings. Every attempt ended in failure.

The experimental turbo on a BMW 801 melted after 15 minutes at full boost. Another shattered under the stress of uneven casting. The materials simply could not survive what the Americans incanel alloys endured as routine. Desperation began to drive decisionmaking. If Germany couldn’t build engines that lasted, it would build engines that burned brighter for a moment. The ME262 became that obsession.

Jet propulsion was fast, sleek, revolutionary, and catastrophically unreliable. Each Jumo 004 engine lasted an average of 25 flight hours before needing replacement. Pilots described the takeoff procedure as gambling with fire. One burst of throttle too fast and the turbine blades would rip free, shredding the engine from within.

Still, Berlin demanded production. The logic was seductive. If one machine could outfly the enemy, perhaps quantity wouldn’t matter. But war doesn’t honor perfection that can’t be produced. In contrast, the Americans built their imperfect machines by the thousands. A single plant in Evansville, Indiana, produced more P47s in 1944 than Germany manufactured all models of FW190s combined.

Each one carried the same R2800, the same reliability, the same margin of survival. The Luftvafa was bleeding to death in statistics it never saw. In July 1944, Henchel was invited to attend a technical conference in Augsburg where senior engineers debated future priorities. The tone was defiant. Our designs remain superior, one declared, their strength is waste. Ours is genius.

Henchel listened quietly, then stood. Genius, he said, requires fuel. The room went silent. Everyone understood what he meant. The genius of German engineering had reached its limit. It could not feed the machines it built, nor protect them from the reality of scarcity. By autumn, Allied bombers were striking refineries at Luna and Mersburg daily.

Without high octane fuel, the Luftwaffa’s piston engines lost power, their superchargers starving for pressure. Meanwhile, the R2800 roared over Europe on a steady diet of 100 octane gasoline refined in Texas and shipped through convoys too numerous to stop. Every flight, every sorty, every escort mission was a demonstration of the same unromantic principle. Logistics win wars.

In one of his final reports before the wars end, Henchel wrote a single line that later historians would quote again and again. They built engines for soldiers. We built them for engineers. It was both confession and epitap. The R2800 didn’t defeat the Luftvafa through innovation. It defeated it through indifference to limitation. It was a machine that asked no favors and offered no fragility.

In it lay the entire strategy of a nation that could afford to break things faster than its enemies could build them. When Berlin fell in May 1945, the surviving technical staff at Rushland burned their notes. Henchel didn’t. He packed his sketches and alloy samples into a small case, believing that one day someone would need to remember what they had learned too late.

Years later, when the Allies occupied the ruins, American engineers found those notes among a pile of abandoned documents. One scribbled margin caught their attention. The engine is not what frightens me. What frightens me is how many of them they can build. That sentence summed up everything the Luftvafa had refused to understand.

Power was no longer about horsepower or speed. It was about the ability to reproduce excellence endlessly. If you think wars are won by invention, press one in the comments. If you believe they’re one by endurance, hit like and subscribe because in the next chapter, when the war ended, Henchel would finally face the Americans and see the machine that had haunted him not in ruins, but reborn in peace.

When the war ended, silence returned to the hangers that had once echoed with the shriek of engines and the clang of wrenches. Reclan was a graveyard now. The test benches stood empty. The blueprints scattered across floors coated in dust and oil. Otto Henchel lingered there for weeks long after most of his colleagues had fled west to avoid Soviet captivity.

The war that had consumed his youth was over, and the machine that had defined his obsession, the American R2800, had outlived the Reich that tried to study it. He often walked the length of the hanger in the early morning, stopping beside the workbench where the engine had once been laid open like a heart.

They built for tomorrow, he murmured to no one. By late 1945, the Allies had begun dismantling what remained of Germany’s aviation industry. American officers arrived at Reclan with cameras, notebooks, and translators. They weren’t looking for secret weapons. They were looking for people who understood them. Henchel was one of the few engineers who hadn’t vanished.

When the Americans questioned him about the R2800 analysis, he told the truth they had learned everything they could and nothing they could use. One of the officers smiled. Then you were studying a mirror, he said.

A few months later, under the program that came to be known as Operation Paperclip, Henchel was invited to work in the United States. He hesitated. His family had survived the bombings of Hamburg only to live now under occupation, and the idea of working for the victors felt like betrayal. Yet the chance to see the country that could build such machines drew him more strongly than pride.

In 1947, he arrived in Connecticut, not far from East Hartford, where the Pratt and Whitney plant still thundered day and night. The first time he walked through the factory, he stopped in astonishment. It was louder than any foundry he had ever imagined. Rows of lathe sparks from welding torches and cranes lifting polished crank cases the size of automobiles.

Women in overalls checked tolerances with micrometers. Men in aprons fitted piston rings with the precision of surgeons. And everywhere the smell of cutting oil and hot steel. He realized that this noise, this chaos, was not disorder. It was power made visible. When an American engineer recognized his accent and asked what he thought of the plant, Henchel paused.

“It’s like watching mathematics being born,” he said quietly. The man laughed. “No,” he replied. “It’s just Tuesday.” Over the following years, Henchel contributed to experimental jet projects, working alongside former German and American engineers alike. Many of them had once tried to kill each other. Now they compared turbine designs over coffee trading secrets like old soldiers comparing scars.

The R2800’s lessons lived on in every new engine, overbuilt bearings, redundant ignition, generous cooling margins. The philosophy of durability had become doctrine. Yet Henchel never stopped thinking about the moment he first opened the Thunderbolts engine. In his notes, he wrote, “It wasn’t their genius that defeated us. It was their patience.

They built not for victory, but for continuity. When Pratt and Whitney engineers asked him to review the new J57 jet engine, he recognized echoes of the double Wasp everywhere. The same emphasis on temperature control, the same obsession with reliability over elegance. He smiled and signed the report.

History, it seemed, was repeating itself only faster. In 1954, he attended an air show in New York where a restored P47 Thunderbolt taxied onto the runway. Its radial engine roared to life with that deep, confident growl he remembered from Wrestling. As the aircraft climbed into the blue, trailing a halo of exhaust, the crowd applauded.

No one around him knew that decades earlier he had taken that same engine apart, bolt by bolt, trying to understand how to defeat it. Watching it soar, he felt no bitterness, only a strange sense of gratitude. The sound was more than mechanical now. It was historical. It was the echo of an age when strength had meant survival.

Years later, long after he retired, Henchel wrote a final letter to a former colleague who had remained in Germany. We learned too late he wrote that perfection dies young. The machines that last are the ones built to forgive our mistakes. The R2800 had become more than an engine.

It was a philosophy one that bridged peace and war destruction and rebuilding. It taught that power wasn’t the ability to make the perfect machine, but to make it again and again and again. Every turbine that spun afterward, every jet that roared into the sky, carried a trace of that lesson, born in the fire of 1944.

If you believe history is written by Victors, press one in the comments. If you believe it’s written by engineers, hit like and subscribe because the story doesn’t end with victory. It ends with understanding. History rarely remembers the men who turned wrenches. It remembers the pilots, the generals, the speeches shouted over radioatic, but not the quiet figures who bent over engines in dim workshops and tried to make sense of metal. Yet, it was in those workshops that the future was forged.

Otto Henchel knew this better than most. In the decades after the war, he carried one truth with him. Machines do not care about flags. They only reveal the truth of those who build them. In 1962, he visited a museum in Washington DC while consulting for an aerospace project. There, beneath a polished glass dome, stood a restored Pratt and Whitney R2800 engine, immaculate silent, preserved as if time itself had paused to honor it.

He stepped closer, reading the small brass plate engine from a P47 Thunderbolt 1944. The same year he had first opened one in Reclan. He ran his hand along the cool metal and felt something he hadn’t expected, not regret, but recognition. The guide nearby explained to a group of school children how this engine had powered the fighters that won the air war over Europe. It was strong enough to take bullets, she said proudly.

It never quit. Henchel smiled faintly. She was right, but not in the way she meant. The engine’s true strength was not in its horsepower or its armor. It was in the civilization that built it, a civilization that had understood that durability is mercy, that forgiveness in metal can save lives. He looked around the hall and saw other relics.

A mosquito bomber, sleek and wooden. a Sherman tank, squat and practical, and beyond them the early jets that would soon conquer the sky. They were all different shapes, different nations. But they shared one secret. They had been built by people who believed that the simplest design made in great numbers could outlast brilliance made in isolation.

The echo of that philosophy rang through every rivet and bearing. Outside, the world had changed. The Cold War had turned engineering into another kind of arms race. The new aircraft Henchel helped design flew higher, faster, deadlier, but also more fragile, more complex, more dependent on perfection. Sometimes when a test engine failed on the stand, he would think of the R2800 and how it had never asked for perfection. It had only demanded care.

He wrote in his final notebook, “Every machine is a reflection of its maker’s soul. The Americans built for endurance, and they endured. We built for glory, and glory burned out.” That sentence became his private epitap. He never sought credit for his wartime work. He considered it a lesson, learned too late and too dearly.

When Otto Henchel died in 1971, his papers were donated to a university archive. Among the sketches and notes was a single photograph, a black and white image from Reclan 1944. It showed a group of mechanics standing around a massive radial engine under a hanging lamp. Their faces were young, serious, unaware that they were staring at the future. On the back in his handwriting were four words.

The day we understood. The echo of steel still speaks. It speaks through every jet that takes flight. Every factory that hums in the night. Every engineer who chooses reliability over pride. It reminds us that the machines we build are mirrors and that progress like mercy comes not from brilliance but from endurance.

News

CH1 Japan’s Convoy Annihilated in 15 Minutes by B-25 Gunships That Turned the Sea Into Fire

At dawn on March 3rd, 1943, the Bismar Sea lay quiet under a pale sky stre with clouds. The air…

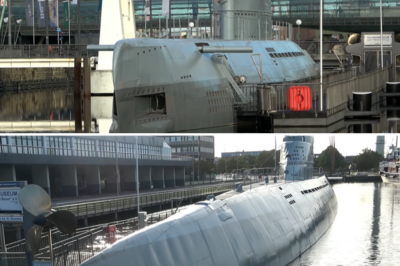

CH1 German WWII Type XXI Submarine Walkthrough & Tour – The Wilhelm Bauer/U2540

in the Final Phase of World War II the German Navy commissioned a revolutionary new type of Submarine design a…

CH1 The Grueling Life of a WWII German U-Boat Crew Member

british prime minister winston churchill famously remarked after the war that the u-boat was the only thing that truly scared…

CH1 U-530: The U-Boat That Escaped to Argentina

At dawn on July 10th, 1945, Argentine fishermen off the naval base at Mardel Plata saw an unexpected silhouette emerge…

CH1 This Was the CHILLING LIFE of Germans Inside a SUBMARINE!

German submarines known as Yubot were a key part of national socialist naval strategy. They were small cramped vessels where…

CH1 What Happened When the 1st SS Met Patton’s Elite at the Bulge?

By the end of 1944, after a series of military defeats on both fronts, the Third Reich found itself on…

End of content

No more pages to load